Odoo Manufacturing Module Explained: Features, Benefits, and Use Cases

-

- Odoo’s Approach to Lean Manufacturing

- The Odoo Manufacturing Process:From Idea to Delivery

- Key Capabilities & Features

- Why Manufacturers Are Switching to Odoo

- Real-World Use Cases and Scenarios

- Planning, Scheduling, and Capacity Management

- Traceability, Analytics & Reporting

- Integration Across Odoo Ecosystem

- Common Implementation Concerns

- Conclusion

- iProgrammer: Your Trusted Odoo Partner for Manufacturing Success

Global manufacturers lose 50% more because of production inefficiencies, delays, and unnecessary downtime. In an age where speed is as crucial as performance, disintegrated workflows and legacy systems are no longer viable. Operations leaders today require real-time output, traceability, and control of every phase of the production process. The window for error is smaller, and the demand for quickness, compliance, and lean execution has never been greater.

This is where the Odoo Manufacturing Module comes into play. Way more than a standard MRP or ERP, it consolidates fundamental manufacturing processes such as production planning, quality control, maintenance, and product lifecycle management, into one unified system that’s designed for today’s high-performance teams. In this blog, we’ll unpack the full depth of Odoo for Manufacturing, walk through its end-to-end capabilities, features, and explore how industry leaders are using it to drive efficiency, resilience, and measurable growth.

The essence of lean manufacturing is not just about reducing waste—it’s about building systems that learn, improve, and adapt with minimal friction. Odoo offers a platform that embeds lean thinking into every layer of the manufacturing process. From configurable work order flows to tablet-based shop floor dashboards, the system encourages streamlined communication, continuous feedback, and real-time decision-making—without adding operational complexity.

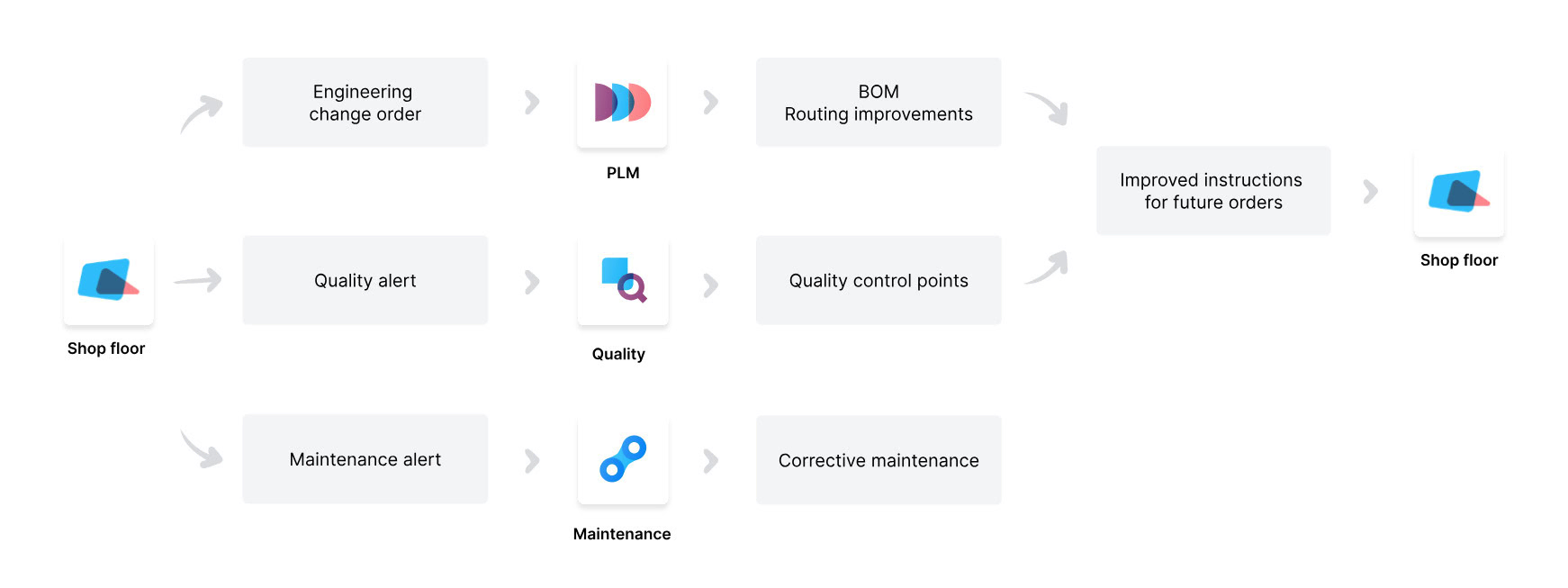

What makes this architecture so strong is that it allows for structured improvement loops. Engineering Change Orders (ECOs), Quality Alerts, and Maintenance Feedback are not separate functions; in Odoo, all of these can initiate pre-programmed steps—new instructions, revised routings, or corrective maintenance—that directly impact future orders. It’s a system that logically follows along Kaizen philosophies and Six Sigma guidelines, allowing teams to respond to observations, streamline workflows, and enhance quality without interrupting operations.

With the unification of MRP, MES, PLM, Maintenance, and Quality under one interoperable platform, Odoo does away with fragmentation, which retards improvement cycles. Manufacturers are able to access insight where it happens, on the shop floor, and force disciplined change with minimal lag.

From Idea to Delivery

Odoo Manufacturing process mirrors how modern production works—fluid, multi-layered, and deeply dependent on timing, materials, and traceability. Whether you’re producing in batches, to order, or managing complex routings across multiple workstations, Odoo brings each step under coordinated control. Here’s how the typical manufacturing flow unfolds in Odoo:

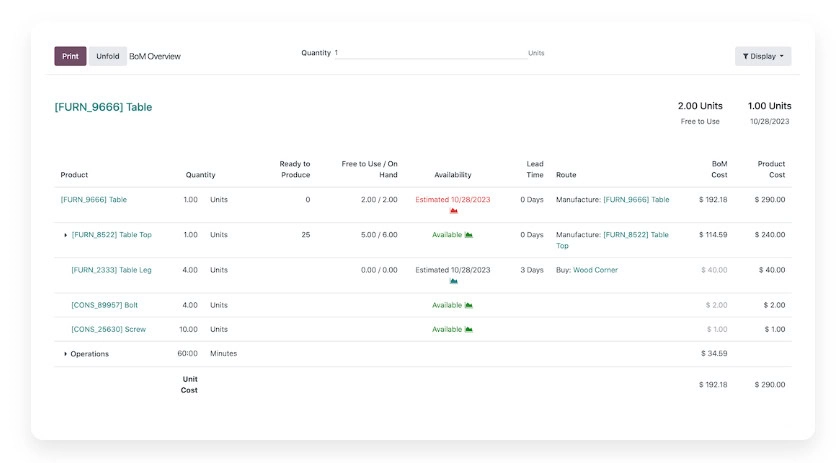

- Define the Bill of Materials (BoM):

Begin with specifying each component, sub-component, and by-product needed. Odoo BoMs handle version control, nested hierarchies, and even product kits, allowing for standardization and customization. - Configure Routings and Work Centers:

Define where and how the product will be assembled. Routings can specify sequencing, work instructions, and time estimates, and each work centre monitors availability and capacity. - Schedule Production with MPS and Gantt Tools:

With Master Production Schedule and real-time planning capabilities of Odoo, manufacturers can test capacity, review material availability, and optimize production schedules—all prior to the start of execution. - Launch Manufacturing Orders (MOs):

MOs can be generated manually, from sales orders, or via replenishment rules. These tie directly to BoMs, routings, and work orders, providing clear execution instructions on the shop floor. - Execute Work Orders on the Floor:

Operators use the Workshop app on tablets to see worksheets, scan barcodes, adhere to predetermined steps, and initiate quality checks—online or offline. - Monitor Quality and Maintenance in Real Time:

Quality control checkpoints, notifications, and statistical checks may be inserted at any step. Feedback from operators or machine performance can trigger maintenance workflows or corrective actions. - Track Outputs, Costs, and Traceability:

Every run of production includes complete cost outturns—material, labour, overhead—with traceability in full through batch or serial numbers. These metrics complete the loop for analysis, regulatory compliance, and constant improvement.

Core Manufacturing (MRP & MES)

The foundation of Odoo Manufacturing lies in its robust support for both Make-to-Order and Make-to-Stock workflows, with flexible controls for managing production complexity.

The foundation of Odoo Manufacturing lies in its robust support for both Make-to-Order and Make-to-Stock workflows, with flexible controls for managing production complexity.

- Manufacturing Orders: Create and manage production runs, triggered by demand or stock rules.

- Work Orders: Break down operations by routing steps for parallel or sequential execution.

- Editable Production Orders: Modify orders even after they’ve been completed, for retroactive accuracy.

- Unbilled Orders: Disassemble products and recover components as needed.

- Kits: Sell products delivered as individual components for post-sale assembly.

- By-products: Track and account for secondary materials or outputs.

- Manual vs Assembly Line Setup: Choose between discrete or flow-based configurations based on your process.

Workshop App (MES)

The Workshop App brings paperless execution to life with real-time dashboards and workstation-specific control panels.- Tablet-Ready Control Panel: Operators can see tasks, capture production, and view work instructions without any hindrance.

- Offline Mode: Ensures that operations run without a hitch even when network connectivity is lost.

- Paperless Operations: Substitute printed worksheets with real-time, context-relevant digital steps.

- Real-Time Work Order Steps: Define and trigger multi-step operations like barcode scanning, checks, or images.

- Feedback System for Kaizen: Workers can flag inefficiencies or suggest improvements from the shop floor.

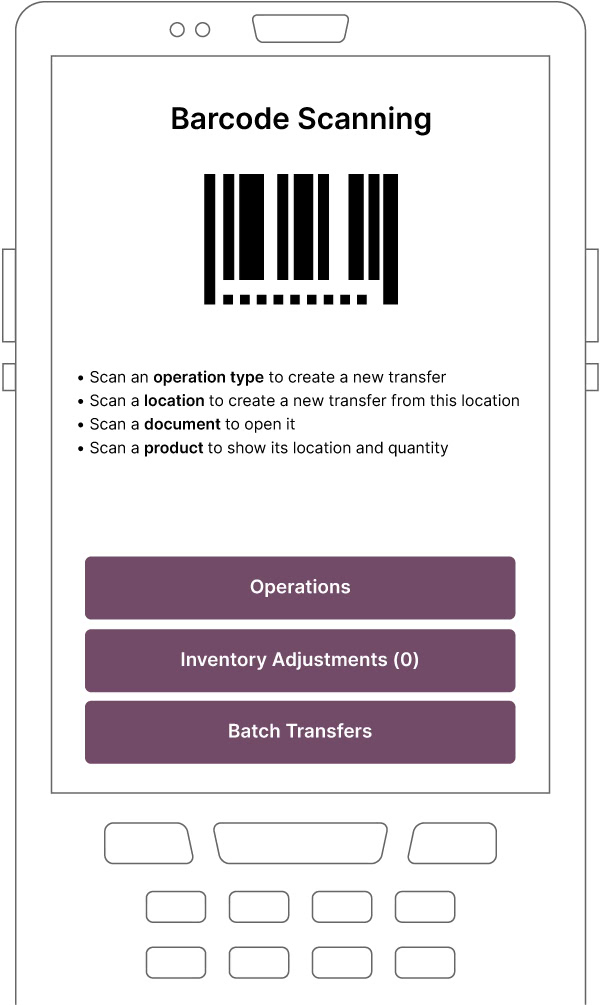

Barcode App

Barcode scanning is integrated across manufacturing functions to increase speed and minimize errors.

- Scan Serial Numbers, Lots, Products: For traceability, inventory checks, and quality steps.

- Trigger Actions: Initiate/pause timers, flag operations as complete, or initiate maintenance requests.

- Accelerates Production: Decreases manual data entry, enables hands-free workflow, and decreases errors.

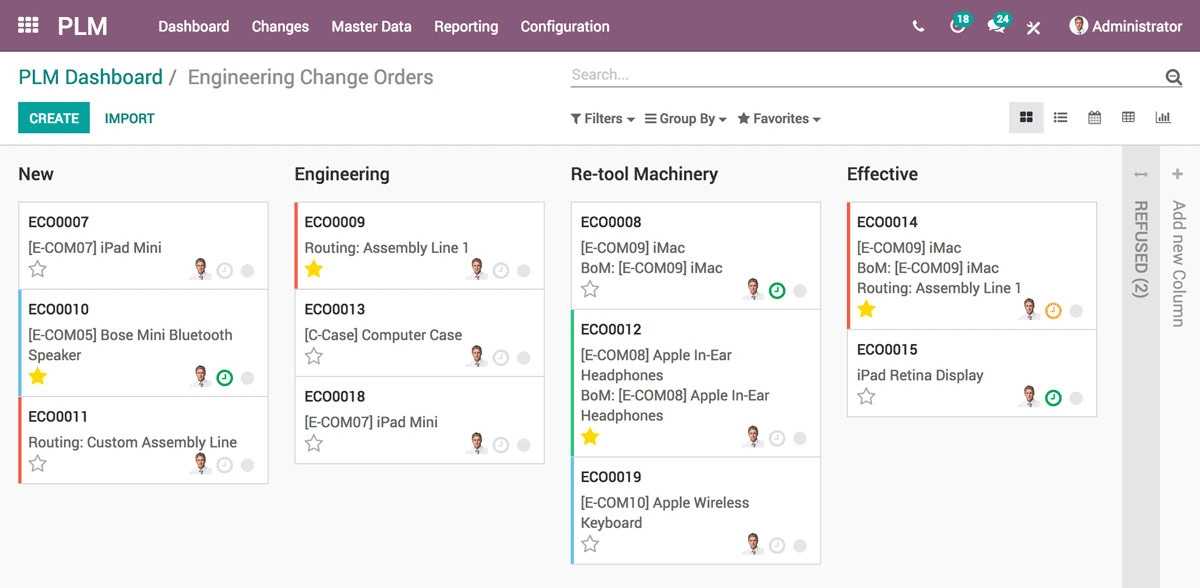

PLM (Product Lifecycle Management)

- ECOs (Engineering Change Orders): Organize and monitor BoM, routing, or document changes.

- Version Control: Manage and compare past versions to follow the evolution.

- Document Attachments to BoM: Embed drawings, test instructions, or manuals directly in product records.

- Change History Tracking: Visualize the progression and approval path of each product change.

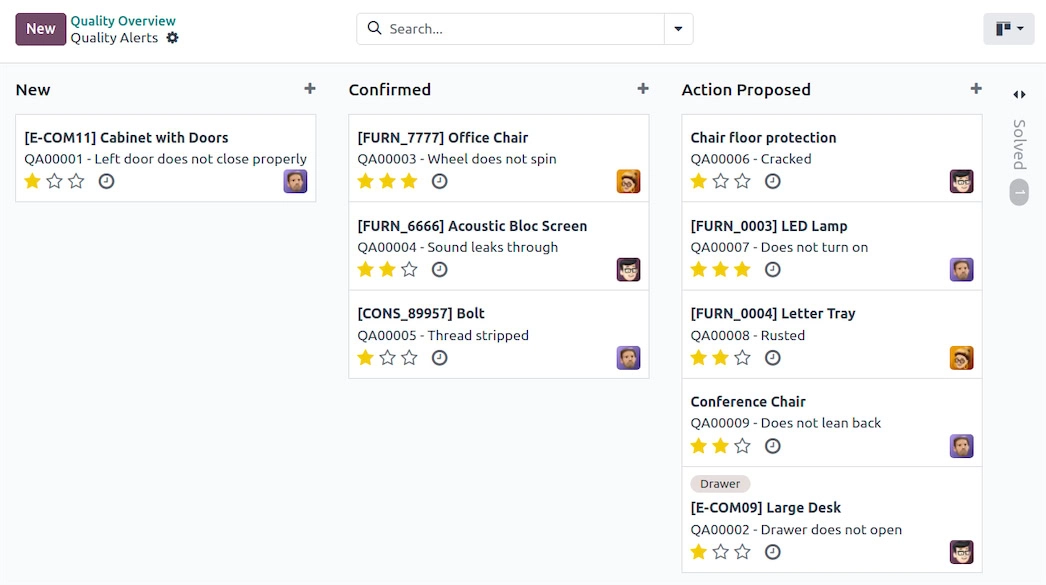

Quality Control

- Checkpoints and Alerts: Automatically initiate checks at critical points in the routing.

- Quality Control Points: Customize for each product, stage, or operation.

- Six Sigma Tools: Deploy statistical methods for variance analysis and process monitoring.

- Statistical Process Control: Capture and track quality metrics over time for each work centre.

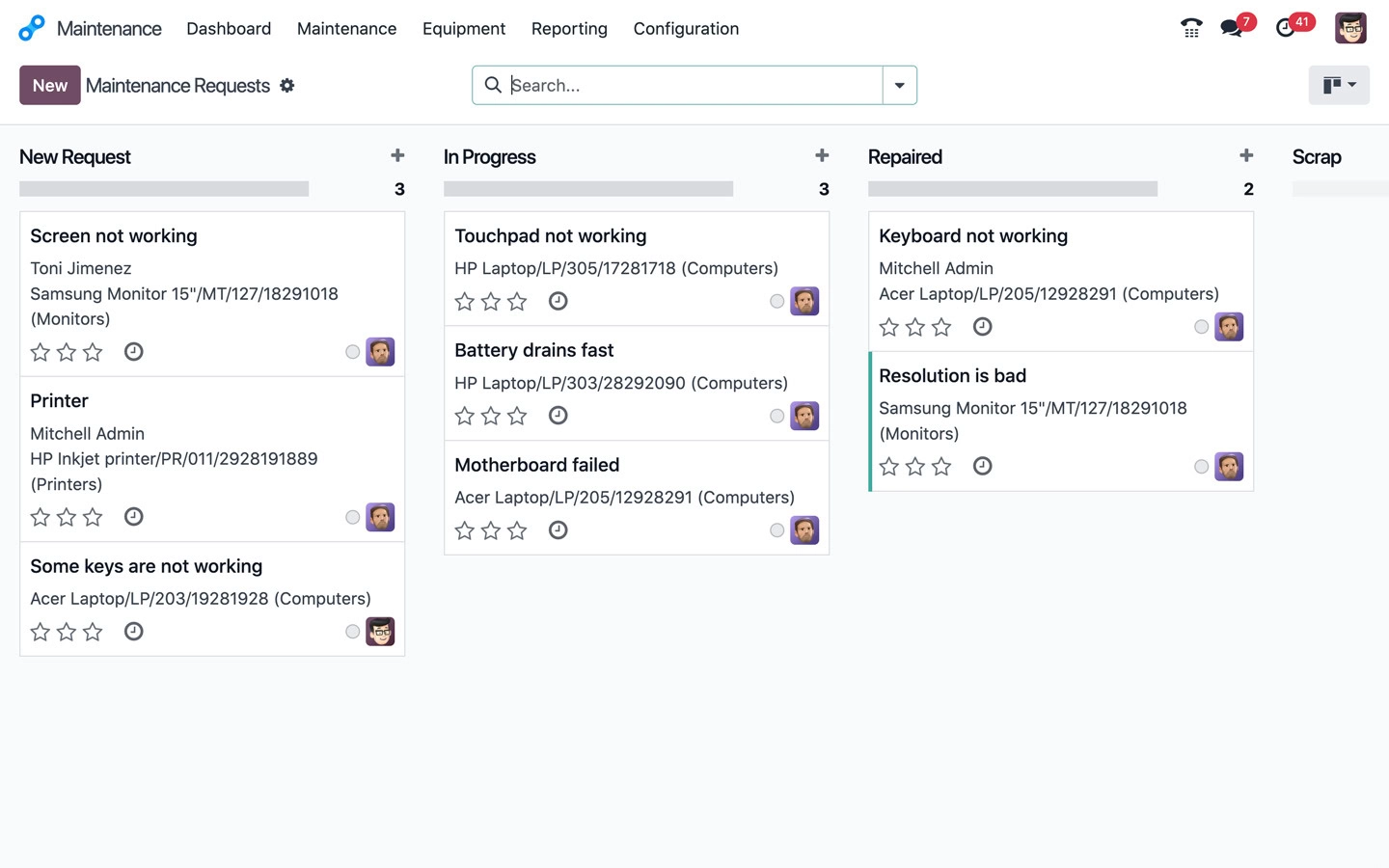

Maintenance Management

- Preventive & Corrective Actions: Time, usage, or performance-based.

- Calendar-Based Scheduling: Schedule interventions visually and allocate resources accordingly.

- KPI-Triggered Actions: Initiate maintenance automatically based on thresholds (e.g., temperature, run-time).

- MTBF & OEE Tracking: Track key reliability and efficiency metrics at workstations.

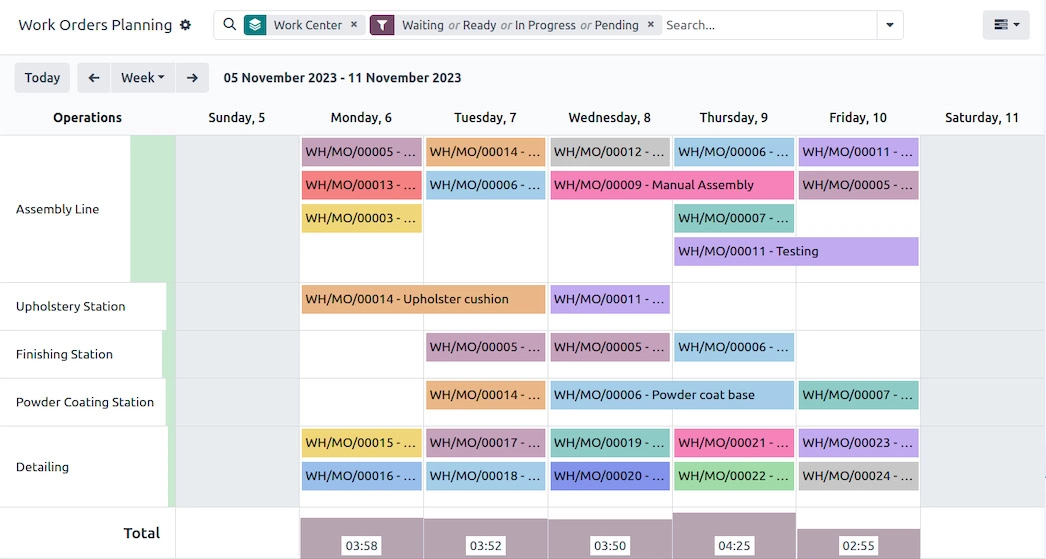

Planning Tools

- Master Production Schedule (MPS): Plan against demand with forecasted production.

- Gantt Chart for Planning: Reschedule or reprioritize operations in an interactive environment.

- Workstation Capacity & Scheduling: Allocate based on availability and efficiency scores.

- Finite Capacity Planning: Avoid over-commitments by simulating load in advance.

- Routing & Optional Flows: Create primary and alternate paths for adaptable manufacturing sequences.

Advanced Configurations

Designed for growing and evolving operations, these tools bring configurability to product setup and repair.- Version Changes: Manage evolving products and trigger new workflows as needed.

- Flexible Reference Data: Modify routings, materials, and options on the fly.

- Create Multi-Level BoMs: Build nested assemblies with component-level traceability.

- Custom Routes for Sequencing: Define conditional flows depending on batch, order, or product.

- Repair Orders & Reverse Logistics: Manage warranty repairs or disassembly workflows directly.

Odoo Manufacturing presents a compelling option over silo software stacks, reconciling strategic insight and operational effectiveness in a single, integrated solution.

Strategic Benefits

Odoo offers producers a platform that bridges long-term operating goals to everyday delivery—without the need for expensive customization or vendor lock-in.

- Unified Platform: Integrates MES, MRP, PLM, Quality, Maintenance, and IoT—simplifying complexity across all dimensions

- Lean-Compliant: Support for Six Sigma, Kaizen, and real-time shop floor to engineering feedback

- From Planning to Execution: Links S&OP decision to production orders, routings, and inventory movements

- Scalable & Modular: Begin with core manufacturing, branch out to CRM, Inventory, or Finance as your business grows

- Open-Source Foundation: Freedom to extend, integrate, or scale without being held back by licensing limitations

Operational Benefits

Manufacturing performance on a day-to-day basis becomes better with Odoo’s real-world, execution-oriented tools that are made for speed, precision, and flexibility.

- Reduced Errors and Duplication: Real-time data synchronization between manufacturing, inventory, and sales reduces risks of manual entry

- Mobile and Offline Ready: Shop floor teams can process work orders, scan barcodes, and log production—even without internet

- End-to-End Traceability: From serial numbers to quality control points—complete visibility across materials and operations

- Real-Time Capacity and Cost Simulation: Simulate production plans with actual resource loads and material costs before execution

- Paperless Workflows: Tablets, dynamic worksheets, and automated quality triggers accelerate cycle times

- Continuous Feedback Loop: Operators can mark problems or suggest improvements in real time—shortening the improvement loop faster

Below are real-world examples illustrating how companies from diverse industries use Odoo to solve problems and expand businesses.

Use Case 1: Discrete Manufacturing – Industrial Equipment Assembly

Context: A mid-range industrial equipment manufacturer experiencing high-mix, low-volume production needed increased engineering change control and component traceability.

Challenges:

- Frequent BOM revisions with poor version tracking

- Delays from disconnected Quality and Maintenance systems

- Limited visibility into real-time work centre loads

How Odoo Helps:

- PLM module tracks ECOs with version history tied to each product

- Maintenance requests triggered from the shop floor via the tablet interface

- Master Production Schedule and Gantt planning streamline resource allocation

Outcomes:

- 25% reduction in change implementation time

- Maintenance-related downtime dropped by 18%

- Engineering and shop floor now operate from a shared version of truth

Use Case 2: Process Manufacturing – FMCG & Consumer Products

Context: A fast-growing personal care brand producing multiple SKUs across seasonal lines faced inefficiencies in raw material planning and batch tracking.

Challenges:

- Stockouts and overproduction due to inaccurate planning

- Manual quality checks resulting in inconsistent compliance

- No centralized way to manage by-products or packaging kits

How Odoo Helps:

- MRP and Inventory integrated for real-time raw material forecasting

- Quality control points automated at each production stage

- Kits and by-product management handled within the same BoM framework

Outcomes:

- Inventory carrying cost reduced by 20%

- Quality non-conformance reports dropped by 30%

- Faster SKU setup and turnaround during seasonal spikes

Use Case 3: Custom Manufacturing – Contract-Based Fabrication

Context: A contract manufacturer handling design-to-order projects lacked alignment between project timelines and manufacturing execution.

Challenges:

- Separate tools for project planning and production tracking

- Difficulty adapting production to mid-project design changes

- Delays in approvals due to poor document flow

How Odoo Helps:

- Seamless integration between Odoo Project, PLM, and Manufacturing

- ECO workflows linked to project tasks and BoM updates

- Document attachments visible at each work centre via the Workshop app

Outcomes:

- 2-week reduction in average project delivery timelines

- Increased responsiveness to design changes

- Stronger audit trail for client approvals and regulatory checks

Odoo accommodates finite capacity scheduling so that production plans are tied to real-world machine, workstation, and labour availability. Instead of overwhelming resources or consuming time with spreadsheets, production planners can simulate realistic workloads and identify constraints before impacting timelines.

- Gantt Chart Scheduling: Drag and drop work orders to see and move them. The interactive Gantt chart allows planners to reschedule jobs, shift timelines, and optimize throughput without having to switch tools.

- Work Center Efficiency: All the workstations are tracked for availability and Overall Equipment Effectiveness (OEE). This implies that planning is conducted based on machine performance and downtime patterns, not on theoretical capacity.

- Multi-Level Assembly Scheduling: Odoo supports nested production processes with great efficiency. Multi-level Bills of Materials (BoMs) are scheduled so that sub-assemblies are synchronized with assembly lines.

- Sales and Inventory-Based Planning: In case of make-to-stock or make-to-order logic, Odoo dynamically associates production schedules with incoming sales orders and existing stocks. Production is only initiated when required—and realigned when conditions are altered.

All production slippages—whether raw materials availability, work centre slippages, or quality changes—can be monitored, audited, and analysed with Odoo MRP. Parts and end products can be batch and serial numbered by manufacturers and enjoy end-to-end upstream as well as downstream visibility throughout the supply chain.

- Traceability Reports: Access to the total lifecycle of any product, part, or work order at a moment’s notice. This streamlines conducting audits, generating compliance reports, and analysing root causes.

- Cost Analysis per Production Order: Follow the actual cost of material, operations, and labour per job. Determine areas for improvement and optimize pricing accuracy over time

- Synthetic Rate of Return: Measure operational throughput by a calculated perspective of production velocity vs. projected output.

- OEE (Overall Equipment Effectiveness): Monitor availability, performance, and quality losses at the work centre level.

- MTBF (Mean Time Between Failures): Track machine reliability and schedule preventive maintenance on the basis of actual performance—not speculation.

By situating traceability and analytics alongside planning and execution in the same place, Odoo MRP eliminates the delays and visibility gaps that can come with disconnected systems. Not just does this enhance operational resilience, but it also provides a basis on which leaner, more intelligent decision-making can begin to gain traction—at shop floor and boardroom levels.

Arguably the most compelling of the Odoo Manufacturing Module’s strengths is its deep and native integration throughout the wider Odoo ecosystem. Instead of depending upon third-party connectors or bolt-on software, manufacturers have a single platform in which planning, production, sales, inventory, and accounting all share the same language—by design.

- Odoo Sales

Production planning can be triggered directly from confirmed quotes or sales orders. For custom or make-to-order products, manufacturing is automatically aligned with customer demand—reducing lead times and overproduction. - Odoo Inventory

Inventory levels are synced in real time with manufacturing activity. As raw materials are consumed or products completed, stock is updated instantly. The system also generates replenishment proposals based on lead times, availability, and preferred vendor routes. - Odoo Accounting

Production expenses are automatically tracked, correlating labor, overheads, and material consumption to every manufacturing order. This makes it possible to cost jobs accurately and have real-time financial visibility. - Maintenance, Quality, and PLM

Odoo Manufacturing integrates natively with its Maintenance, Quality, and PLM modules—eliminating the need for external systems. Engineering changes, quality alerts, and maintenance triggers are part of the same operational workflow. - Odoo IoT

With IoT Box integration, manufacturers can link machines, sensors, and barcode scanners directly with the system—entering real-time measurements, initiating actions, or recording events without human intervention. - Odoo eCommerce & Website

For B2C or D2C manufacturers, Odoo’s Website and eCommerce apps enable make-to-order workflows, where an online purchase can trigger a production order, stock reservation, and delivery—all without leaving the system.

What Business Owners Should Know

Following are the questions most frequently asked by business owners and operations leaders before proceeding.

Can we implement it without disrupting ongoing production?

Yes. Odoo’s modular architecture allows businesses to roll out components in phases—starting with core functions like work orders or BoMs, then layering in Quality, Maintenance, or PLM as needed. Most manufacturers go live while operations continue, with minimal downtime.

Will it integrate with our existing ERP systems, machines, or barcoding tools?

Odoo supports both native integrations and external APIs. Many manufacturers connect it with legacy ERPs during transition or interface it with barcode scanners, printers, and IoT devices using Odoo’s IoT Box. This reduces the cost and friction of full replacement.

How steep is the learning curve—for both floor staff and managers?

Odoo is designed with use in mind. Shop floor interface is touchscreen-capable, task-oriented, and simply laid out—little need for training. For planners and supervisors, dashboards are simple and designed for visual decision-making instead of complicated inputs.

Will it scale if our operations expand significantly?

Yes. With one or many production lines, as you grow, Odoo’s modular design can accommodate your progress—adding more users, workflow, or applications without installing a new platform or re-implementing.

What happens during network outages or in low-connectivity plants?

Odoo’s Workshop application is fully offline-capable. Local storage of production data syncs when connected, ensuring smooth execution in situations where connectivity cannot be predicted.

Modern manufacturing is no longer defined by the number of tools one uses but by the quality of collaboration of those tools. Odoo Manufacturing software is unique not for attempting to do it all but for doing what counts. Modular by nature, it allows you to begin with what you require today—work orders, planning, quality inspection—and expand to more sophisticated workflows such as PLM, IoT, or predictive maintenance, without platform change. The user interface is simple, the logic is good, and its visibility—from machine-level performance to cost-level insight—is revolutionary.

For manufacturers in times of uncertainty, growth, or digital transformation, Odoo Manufacturing provides more than a collection of features. It provides an intelligent system that’s practical, lean-compliant, and ready to grow with you. Ultimately, sustainable manufacturing success doesn’t come from software by itself—but from systems that grow with the business. Odoo is designed for that.

Your Trusted Odoo Partner for Manufacturing Success

At iProgrammer, we’ve spent nearly two decades engineering digital solutions that balance complexity with clarity. It’s this principle—deep capability, delivered simply—that makes our partnership with Odoo a natural fit.

As certified Odoo Ready partners, we’ve helped manufacturers of all sizes implement, customize, and scale the Odoo Manufacturing module to meet real operational goals—without excessive overhead or disruptive transitions. From single-line production units to multi-location manufacturing networks, our team brings grounded expertise across MRP, PLM, Quality, Maintenance, and more.

We customize your workflows, pinpoint essential workflows, and adapt Odoo to your factory floor—from user-friendly workstations and mobile barcode scanners to high-powered planning boards and predictive quality notifications.

And if you’re just getting started, our modular approach and staff augmentation options enable you to start small, go fast, and scale with confidence—whether you require a single developer or a full implementation team.

Whether you’re moving away from legacy ERP or need to leaner, future-proof alternatives, iProgrammer makes it happen—with just the right balance of technical expertise, strategic vision, and real-world manufacturing expertise.

Let’s build smarter systems—together.